Mould CNC Machining: The Future of Precision Manufacturing

CNC machining stands at the forefront of modern manufacturing, offering unparalleled precision and versatility. Among its various applications, mould CNC machining emerges as a crucial process in the production of intricate and high-quality components. At Sumiparts.us, we specialize in providing top-notch services that cater to diverse industrial needs, including Machining, Laser Cut, Welding, Plastic Injection, Vulcanized, and Industrial Supplies.

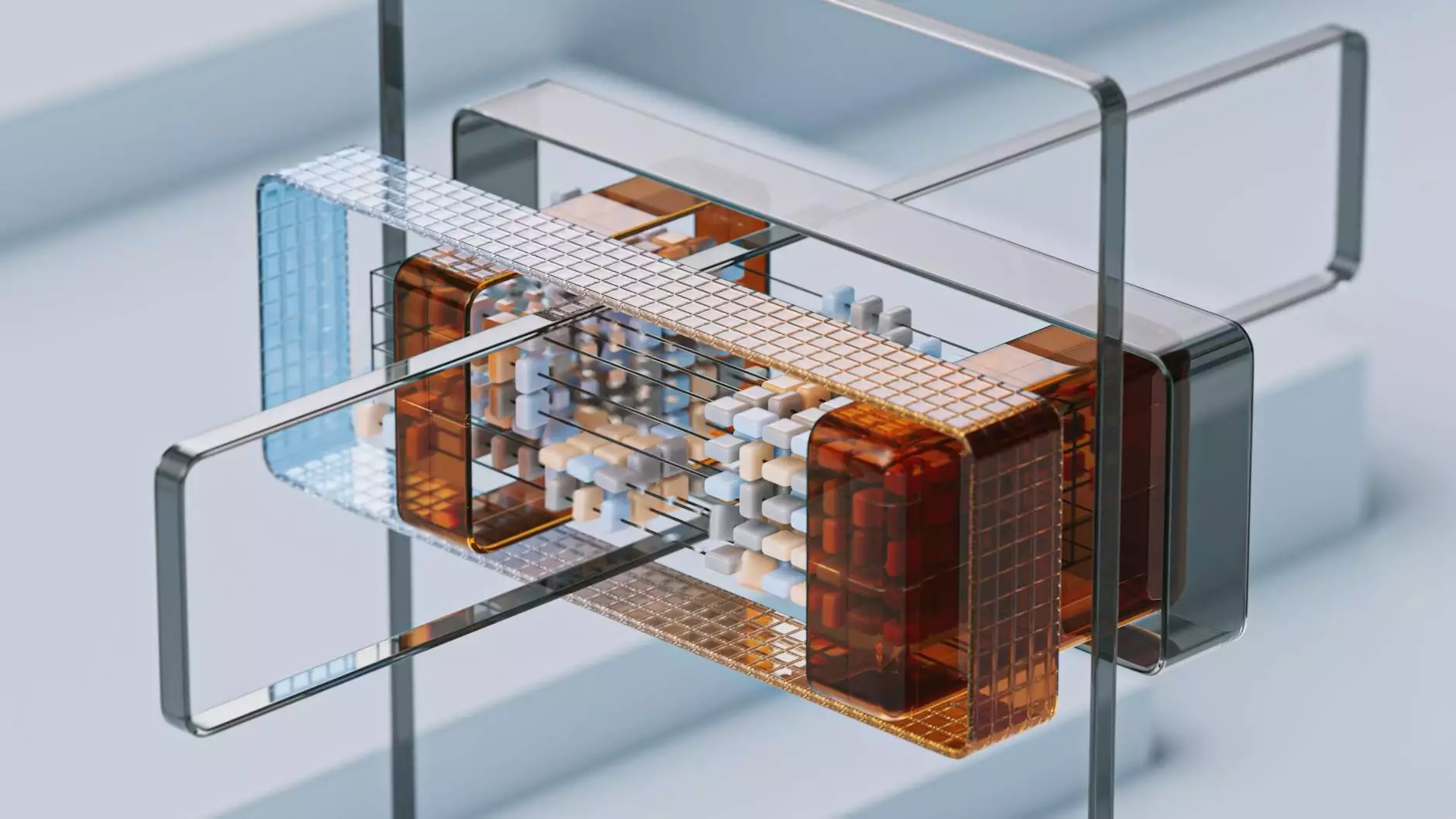

Understanding Mould CNC Machining

Mould CNC machining refers to the process of creating molds using computerized numerical control (CNC) technology. This process is essential in industries such as automotive, aerospace, and consumer products, where precision and reliability are paramount.

The Importance of CNC Machining in Modern Manufacturing

- Precision: CNC machining ensures that each component is produced to exact specifications, reducing the likelihood of errors.

- Consistency: The automated nature of CNC machining allows for high-volume production while maintaining quality.

- Flexibility: Modifications can be easily made to the design, allowing for quick adaptations to evolving market demands.

- Efficiency: CNC machines operate continuously, maximizing output and reducing downtime.

Applications of Mould CNC Machining

There are numerous applications where mould CNC machining plays a pivotal role. Let's delve into some of the key sectors benefiting from this innovative technology.

1. Automotive Industry

The automotive industry relies heavily on mould CNC machining for creating complex parts and molds that fit precisely within vehicles. From custom engine components to intricate dashboard designs, CNC machining enables manufacturers to develop lightweight yet durable parts that enhance the performance and safety of vehicles.

2. Aerospace Sector

In aerospace manufacturing, the stakes are incredibly high; precision is critical. Mould CNC machining contributes significantly by producing components that can withstand extreme conditions. This includes parts for engines, fuselages, and interior components that require exact tolerances for optimal performance and safety.

3. Consumer Electronics

As the demand for consumer electronics grows, so does the need for high-quality molds to manufacture components. Mould CNC machining ensures that electronic devices such as smartphones and tablets have the required precision components, contributing to the overall integrity and functionality of the products.

Benefits of Choosing Mould CNC Machining

The numerous advantages of mould CNC machining make it a superior choice for manufacturers across various industries.

- Cost-Effectiveness: Although the initial investment in CNC machines can be significant, the long-term savings achieved through efficiency and reduced waste make it cost-effective.

- Complex Geometries: CNC machining allows for the creation of complex designs that would be difficult or impossible to achieve using traditional manufacturing methods.

- Material Versatility: Whether it is metals, plastics, or composites, CNC machines can accommodate a wide range of materials.

- Rapid Prototyping: CNC machining enables rapid prototyping, allowing businesses to test and modify designs quickly before mass production.

How Sumiparts.us Excels in Mould CNC Machining

At Sumiparts.us, our commitment to excellence in mould CNC machining is reflected in the quality of our work and the satisfaction of our clients. Here’s how we stand out in the competitive manufacturing landscape:

State-of-the-Art Technology

We utilize the latest CNC machining technology, ensuring that we remain at the cutting edge of precision manufacturing. Our machines are equipped to handle intricate designs and large-scale production runs with ease.

Skilled Professionals

Our team consists of highly trained technicians and engineers who have extensive experience in CNC machining. They are experts in their field, ensuring that every project is executed flawlessly from concept to completion.

Custom Solutions

We understand that each client has unique needs. Therefore, we offer custom solutions tailored to your specific requirements. Our team works closely with clients to ensure their visions are translated into reality, no matter how complex.

Commitment to Quality

Quality assurance is integral to our operations. We employ rigorous testing and inspection protocols to guarantee that every component meets the highest standards of quality and performance. This commitment has helped us build a reputation as a trusted provider in the industry.

Conclusion

In the rapidly evolving world of manufacturing, mould CNC machining represents a beacon of innovation and reliability. As businesses seek ways to optimize their production processes and improve product quality, CNC machining emerges as an indispensable tool. At Sumiparts.us, we are proud to be at the forefront of this revolution, providing high-quality CNC machining services tailored to meet the diverse needs of our clientele.

Whether you are in the automotive, aerospace, or consumer electronics sector, we have the expertise and technology to help you succeed. Contact us today to learn more about how our mould CNC machining services can benefit your business!